Welcome to Marine Courses Center today we will discuss

maintenance vessel | ship painting | ship deck maintenance | seamanship

Iron or steel vessel suffer from rust and corrosion both inside and outside as a result of exposure to water and air.

On the vessels bottom, shells and sea-weeds stick to the bottom and increase as time elapses, showing significant amount of marine growth (called fouling).

This causes negative effect on the vessels’ speed.

That’s, why we have to clean and maintain the vessel.

We use preventive measures against rust (corrosion) and against fouling.

After scaling the surface and cleaning it, paints should apply to the surface for protection.

The Main Components of Paints ship :

The paint consists of a mixture of components with specific ingredients called:

Pigments – Binders – Solvents – Driers.

I- Pigments

It is the basic component giving the colour of paint and the protective quality.

It is in the form of fine powder or paste, such as white lead – red lead – zinc oxide – zinc chromate – aluminium.

II- Binders

gives the paint sticky quality and Holds the pigment particles together.

Binders such as linseed oil or ting oil.

Binders such as linseed oil or ting oil.

III- Solvents

The solvents added to the pigment together with binders as a mixture so that the paint can spread evenly. Solvents such as white spirit – thinner – turpentine (mineral oil) – naphtha or other special chemical products.

IV- Driers

The driers assist the paint film to dry more quickly such as scanty.

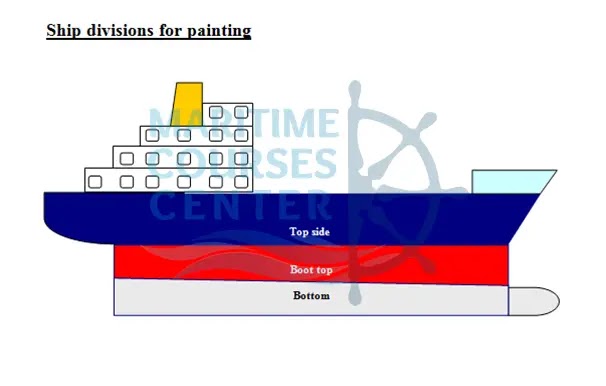

Ship divisions for painting

Types of Paints Used on Board

There are many types of paints used on board vessels such as:

1) Primers:

A type of paint applied directly after scaling and cleaning.

It consists of lead, oxide or chromate base, which give protection against rust.

It has many colours and also it is poisonous.

2) Undercoats:

It is a paint apply over the primer and give flat finish (not glossy) before the top coat, many colours are there, But the base of paint are important for the kind of surface painted.

3) Finishing coats:

The top coat has many colours depending on these used by the shipping company.

It provides a hard glossy cover over the undercoat paint. It is also called Enamel paint.

4) Funnel paints:

It is heat-resisting paint with many colours required by the shipping company.

Synthetic Paints are the fire resisting paint.

5) Silverine:

It is a heat-resistant paint for radiators, exhaust pipes, pipes, ventilators, etc..

6) Bitomastic paints:

Used where high protection against water and anti-static electricity needed, such as bilges, ballast tanks, chain lockers, etc… good finish is not required.

7) Deck Paints:

It is a special paint to resist the foot steps when walking on it.

8) Topside Paint:

It is the paint which is subject to air, rain and sea splashing.

It is supplied in company colours.

9) Boot Topping Paint:

It is a special paint covering the boot top area, which is submerged under water when the vessel is loaded and it is subject to air when the vessel is discharged.

10) Anti-Corrosive Paint:

It is a special expensive paint; apply directly to the steel in the vessel’s bottom.

It is subject always to water.

It is painted only when the vessel is in dock.

11) Anti-Fouling Paint:

It applies on top of the anti corrosive paint to kill weeds and marine growth in dry dock.

The vessel should be placed into water while the paint is still wet not more than twelve hours from the start of painting in dry dock.

12) Varnish paint:

It is used with wooden surfaces.

Preparing the surface for painting

In order to paint a surface, it should be prepared first.

1- Sweep & clean the surface.

2- Chip the rust off the surface.

3- Wire brushes the surface for fines.

4- Wash the surface with fresh water.

5- When the surface dries, Paint the surface with primer lead 2 coatings.

6- Cover the primer lead with undercoat paint 2 coatings.

7- Cover the undercoat paint with finishing coat(enamel) 2 coatings.